Store is an important component of material management. Store keeps the materials such that the materials are well accounted for, are maintained safe, and are available at the time of requirement. Storage is an essential and vital part of the economic cycle and store management is a specialized function, which can contribute significantly to the overall efficiency and effectiveness of the materials function.

The main processes of store are:

· to receive the incoming materials (receiving),

· to keep the materials as long as they are required for use (keeping in custody), and

· to move them out of store for use (issuing).

The main

functions of store are:

1.

Maintain all documents of materials that are able

to trace an item, show all its details and preserve it up to its shelf life in

the manner prescribed or till it is issued for use.

2.

Ensure the safety of all items and materials whilst

in the store which means protecting them from pilferage, theft, damage,

deterioration, and fire.

3.

Efficiently and economically provide the right

materials at the time when it is required and in the condition in which it is

required.

FUNCTION OF

AUTOMOBILE REPAIR SHOP

An automobile

repair shop (also known regionally as a garage or a workshop) is an establishment where automobiles are

repaired by auto mechanics and technicians.

Goals and Objectives:

- To

create a substantial customer base consisting of private and professional

clients both in the domestic and international markets

- To

solve any problem arises in our field and provide quick solutions to all

our customers

- By

achieving compatibility with as many manufacturers and models as possible

- Keeping

our knowledge base up to date

- Maintaining

the professional service and personal care we offer our customers

- Establish our status as sector leaders by providing the highest quality of service possible

FUNCTION OF AUTOMOBILE SERVICE STATION

1.

To carry on all or any of the business with wholesale

and retail dealers for proper inventories.

2.

To undertake the safe keeping, cleaning, repairing,

painting, furnishing, body building, refuelling and servicing of motor vehicles

of all kinds.

3.

fully committed to

our clients, our customer base will increase and will provide a stable ground

for our business to grow.

4.

Interrelation

between various section of service station so that the servicing follows a

structural and organized path.

5.

Proper house keeping is to be done

for cleaning and preparedness for the upcoming service counters to come.

Automotive Items to be

kept in Stores

- Tires

- Automotive exteriors

- Automotive interiors

- Engine compartment

- Automotive plastics modifiers

Coding of

items in stores

There are

different types of store codes designed to suit the requirement. These may be

based upon the type of store item, the Purpose for which items are used or on

any other application of that item. The common methods of store codification

are as follows:

1. Alphabetical

codification

2. Numerical

codification

3. Mnemonic

codification

4. Combined

alphabetical & numerical codification

5. Decimal

codification

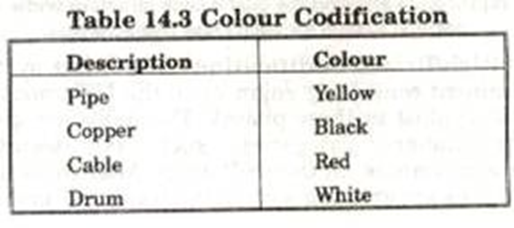

6. Colour

codification.

1. Alphabetical Codification:

In

this method, letters of the alphabet are used to describe an item. Sometimes

combinations of alphabets are designed to give a mnemonic meaning e.g.,

BT-Bolt

NT-NUT

PN-PIN

SC-Screw

RT-Rivet

SM-Steel Mild

SMA-Steel Mild

Angle

SMC-Steel Mild

Channel

Since the numbers of Alphabets are limited, even with a combination of letters as above there is a serious limitation to the number of items which can be uniquely coded under this method. Further, sometimes the same combinations of the alphabets are capable of different meanings.

2. Numerical Codification:

Against

the alphabetical system, the numerical system is based on numbers, simple

numbers, block numbers or dash/stroke numbers. Examples are:

3. Mnemonic Codification:

When

we use letters to help memory, we call such a system a mnemonic system. This

system is therefore, a special application of the alphabetical system.

Alphabets are allotted to an item according to its initials or abbreviation.

For example,

4. Combined Alphabetical &

Numerical Codification:

This

system, as the name suggests, is the combination of both the alphabetical and

the numerical system described before.

5. Decimal Codification:

Under

this system of codification, within the range often numerals 0-9, some

significance is attached to every digit in the code. Thus, the whole range of

items in stores can be codified without difficulty. Generally 7 to 8 digits

will be found sufficient for all practical purposes, but it may also be extended

upto 10 digits in order to accommodate any other characteristic of the material

desired to be described.

6. Colour Codification:

This

system uses colour marking for easier and more ready identification on metals,

bars, pipe, drum and cable.

What is Two-Bin Inventory Control?

Two-bin inventory control involves the storage of goods in two bins, one of which contains working stock and the other containing reserve stock. The amount of inventory kept in the reserve stock bin equals the amount the company expects to use during the ordering lead time associated with that item. To use this system, one should reorder goods as soon as the working stock bin is empty, so

How to Calculate the Reserve Stock

Level

The calculation for the amount of inventory to keep in the reserve stock bin is to multiply the daily usage rate by the lead time, and then add the safety stock amount. The formula is as follows:

(Daily usage rate × Lead time) + Safety stock = Reserve bin quantity

Two-bin inventory control is commonly used for low-value items that can be purchased and stored in bulk, and for which stocks are maintained in the production area, rather than the warehouse.

Lead time in inventory management

It is the amount of time between

when a purchase order is placed to replenish products and when the order is

received in the warehouse.

Example of Two-Bin Inventory Control

LAYOUT

OF STORE

Free flow:

This is a very common type of layout used by small stores which sell a Store Layout and Design single product category like ladies wear or men’s wear or kids wear or furniture or purses etc. In this kind of layout the fixtures and merchandise are grouped into free-flowing patterns.

Grid: This type of

layout is common in supermarkets, drug stores and convenience

Spine: The spine layout

tries to combine the advantages of the free flow layout, the grid layout and the loop layout in a certain way. In this layout there is a

single aisle which takes the customers from the main entrance to the back of the store and the same aisle is used to bring back customers to the front.

Records to be Maintained in the Stores

Various records which must be

kept by store-keeper for easy and smooth handling of stores:

1. Bin Card

2. Receipt of Materials

3. Issue of Materials

4. Store Accounting

1. Bin Card:

This is a card which is attached to each bin, rack, shelf or

other container for stores. A record of all materials entering or leaving the

bin and balance of material in hand is kept in this card. These cards are

entered by the store-keeper and only the quantities are recorded. These should

tally with the quantities of material as shown in the relevant account in the

stores ledger. This will enable the store-keeper to ascertain the quantity of

any material in stock and remind him to requisition of fresh stock, when the minimum

stock has been reached.

2. Receipt/Receiving of Materials:

1. Material is received in the

stores from;

(i) Outside suppliers,

(ii) Production department, and

(iii) Various departments as return of material on material returned note.

When a purchase order placed, a copy is sent to the stores. This helps in

planning necessary arrangements for receipts, like unloading etc.

2. When the material is despatched by the supplier, its intimation is also

received in the stores, which indicate expected date of receipt of material, so

as to enable stores for organising quick and easy clearance.

3. On receipt of supply, it is tallied from the purchase order and despatch intimation and other documents. It is physically verified regarding quantity, size etc. If required, material can be unpacked for physical verification.

4. After physical verification, ‘Store Receipt Vouchers’, generally known as SRVs are prepared and sent to the inspection department.

5. After inspection of material, if it is acceptable, inspection department records the certificate on SRV and return back to the stores, with intimation to the purchase and accounts department.

6. Stores department sends the material to the custody.

7. Rejected material is retained in the rejection cell till they are returned

to the supplier or replaced by him.

3. Issue of Materials:

1. Materials are issued only on

receipt of a properly authorised withdrawal form, which is usually called a

‘Material Issue Requisition Form’ or ‘Store Issue Voucher’ i.e., SIV.

2. On receipt of SIVs, store department issues the materials and records the

quantities disbursed.

3. A copy of SIV, duly entered by the stores regarding issue of material, is

then sent to the accounts department for pricing and entry in the stock ledger.

4. One copy of SIV is sent to the department who has initiated it for

withdrawal of material.

Indent on Store:

It is also called material issue requisition. An important rule,

which should be strictly followed is not to allow any materials to pass from

the stores department into the works except upon the authority of written

requisition.

Material Returned Note:

Material issued for departmental use sometimes are not actually used and returned to the store-keeper. They must be properly recorded and their value may be duly entered in the store records and these values may be credited to the accounts of the department concerned by the cost department. For this purpose, Material Returned Notes are written out in triplicate.

4. Store Accounting:

Accepted materials are accounted

for in the stores and their proper account is maintained. The account of stores

is

maintained by the store keeper in the same way as that of cash by the cashier.

Main objectives of maintaining proper accounts are:

(i) To indicate the quantity and values of stores held.

(ii) To provide information about values of receipts and issues.

(iii) To determine ordering level without physically checking the stock.

(iv) To keep account of total expenditure.

(v) To provide basis for material costing.

(vi) To help in locating and preventing wastage, pilferages, and

misappropriation.

(vii) To help in keeping the level of inventory at a reasonable level.

It is desirable to know at all times as to how much working

capital is represented by stores in stock. The value of stock is also needed to

be shown in balance sheet as an asset. Value of the stock at the start and at

the end of the accounting year is used in preparing profit and loss account.

Material Costing:

Material cost includes material price, freight charges,

insurance, and taxes. Here material price means actual cost incurred by taking

price quoted by supplier as the basis subtracting the discounts and adding any

other expenses not covered in it.

Stores Accounting Records:

In order to maintain an efficient record to stores, following

books and records will be required and these are maintained separately for

different types of materials:

(a) Inward and Outward Registers:

When the material is dispatched

by the supplier through rail, he will send its receipt issued by the railway

authority, called ‘RR’.

(b) Stock Register:

These are:

(i) Dead Stock or Non-Consumable

Register.

(ii) Consumable Register.

(i) Dead Stock or Non-Consumable Register:

This is maintained by store-keeper, in which entries of

non-consumable articles such as all machinery, equipment, furniture etc. are

made.

(ii) Consumable Register:

In this, store-keeper maintains record of consumable stores

received, such as coke, diesel oil, kerosene, petrol, lubricants, cotton waste,

paints etc. The different items are entered on different pages. All the

transactions about a particular item are entered in one page.

(c) Daily Receipt Register:

This may be in a register or loose leaf form. Whenever any

material comes in the store, it is entered date wise in daily receipt register.

Material is then inspected and if found suitable, is entered in Stock Register.

(d) Issue Register:

This may be in register or loose-leaf form. All stores issued

are entered date wise in it by store-keeper. From the Receipt and issue

register, store ledger is prepared by accounts section.

(e) Surplus Stock Register:

Sometimes such purchases are made, which do not come in use for

long time, say 3 years. Such materials are then declared surplus and are

recorded in a separate register called Surplus Stock Register. Thus unnecessary

material is removed from the Stock Register to facilitate easy handling.

(f) Suspense Register:

The defective item or items received in excess should not be placed in the bins but kept in “Suspense cell”, A separate register is maintained by store-keeper for all such items placed in suspense and is known as Suspense Register.

(g) Condemned Article Register:

Unserviceable material after use or obsolete material which is authorised to be condemned by authorized person is entered in this register and will be shown as stock until disposed off. The balance of condemned articles will be taken out from store ledger and will be shown condemned.

(h) Loan Register:

Sometimes non-consumable material is issued from store on loan

for temporary period by the production of slip of authority. Before issuing,

material is entered in this register and signature of the bearer is taken in

this register and slip of authority is

kept safe.

(i) Empty Containers and Packages Register:

The record of empty containers and packages is kept in this

register by store keeper. These should be disposed-off at convenient intervals

by auction or otherwise to the best advantage.